Power Safeguards

A reliable power supply chain helps you run your experiments smoothly, avoid undesired interruptions, and can even protect your samples from damage due to power fluctuations.

When working with an isolated SPI rack, you can think of the batteries as the reservoir that provides instantaneous power to the rack, while the power supply circuits feeds the batteries to keep them at the required charge level. In case of a mains power failures the battery can provide enough time to sustain your experiment until mains power is restored.

If the battery is not proper, you will have less protection in case of a mains power failure. This can be in the form of shorter backup time (in some cases down to zero backup time) or degradation of the batteries voltage level. A short-circuited or leaking battery may exhibit reduced voltage swing and possibly heating of the battery box. If the power supply chain is failing, you will likewise see a degradation of the batteries voltage level. Therefore it is important to verify the functionality of the power delivery circuits regularly and frequently.

The following actions are a part of good practice / recommended routine regarding the SPI supply back-up battery:

Review the battery sticker. A battery that’s aged over 4 years should be replaced. Aging batteries lose capacitance, giving a shorter back-up time. Failing batteries have zero capacitance. In rare events they can even create shorts during your cryogenic experiment. This has happened on a few occasions in the past.

For all batteries you should be able to see the production date. Some are also marked with the expiration date, as shown below.

First, keep the SPI-system powered via gyrator and connected to the battery as usual for at least a day, to reach the steady-state voltage. Then unplug the gyrator supply from the mains to simulate a power failure. Now you can track the duration (usually hours) in which the battery voltage levels remain sufficient for your specified operation.

At the start of this test the full battery voltages should read at least 6V and the acceptable discharge point for specified operation is 5.2V. Do stop this test before the batteries drain to 4V as yet-further discharge could degrade the batteries.

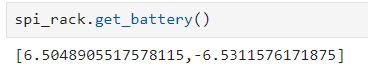

This battery output voltage can be measured directly on unused power input socket backside of the rack or via a connector box available from the electronics team. Always measure in the loaded condition (that is connected to a powered rack). Unloaded measurements are not correct. It can also be conveniently read with the function get_battery() on SPI racks with the C1b/C2 modules. Note that levels read via this function are somewhat lower than those measured directly due to built-in resistance.

For reference, a typical SPI rack with a C1b controller and 2 D5a modules typically runs 29-30 hours (during power failure) on a new fully-charged battery. A rack with a C1b controller and 11 D5a modules (fully populated rack) typically runs 6-7 hours.

The preferred method is the get_battery() function). It is a quick and easy method, run within your control environment.

A slow and progressing drop in battery voltage indicates a failure of both the battery and either mains power or the gyrator. Note that this check does not indicate a battery failure alone. Even with a degraded batteries the gyrator can keep the rack properly powered at correct voltage levels. That is why the prior two tests are essential.

In addition, the battery voltage read-out circuit in the SPI-rack itself starts to malfunction as output levels from a too deeply discharged battery get too low. Consequently, values returned from get_battery() for both positive and negative supplies are only reliable with a positive battery level above 3.8V. Be aware that if you read a battery level of 3.8V or below, the true level might be significantly lower.

Note: The effect of battery failure on the instrumentation is not always trivial. In some cases it can cause harm to samples. As an example, we will consider the impact on the D5a voltage-source module. Once the SPI rack’s power supply levels reduce beyond certain points, the D5a voltage outputs may scale down gradually, shift off center, sharply drop to 0, then sharply scale up likely beyond the original set point. Information stored in the D5a is also corrupted and lost.

The following methods are recommended practice when dealing with the power delivery chain for the IVVI or SPI racks:

There are additional tips and good practices to preserve your battery shelf life:

The image below shows four batteries located in unobstructed free air and separate from instrumentation.